SiedarcTM electrodes

|

||||||||||||||||||||||||||||||||||||||||||||

Connection type

|

Application

|

Example

|

| Daisy chain | In-line through connection to immersed grounding

terminal. No cable. |

|

| ECon | Crimp-it-yourself economical lug-type connector. No cable. |

|

Perpendicular |

Highest quality connection for perpendicular cable

run. Highly recommended for exposed locations. Cable in 4' & 8' lengths. |

|

Parallel |

Highest quality connection for parallel cable run. Highly recommended for low clearance applications. Cable in 4' & 8' lengths. |

|

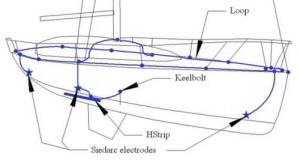

The daisy chain connection is intended to be used whenever a cable run passes by a SiedarcTM electrode with an ultimate termination on an immersed terminal such as a HStripTM, or keelbolt. In The EHLoopTM, as shown in the diagram above, both the daisy-chain SiedarcTM electrode and an HStripTM are connected into a continuous loop that also includes the mast base and chainplates.

The EConTM connection comprises a heavy-duty lug that has been rounded off and tinned to minimize sideflash risk from the connection. All connecting surfaces far exceed the cross sectional area of the cable.

In both parallel and perpendicular connections the cable is rotary swaged onto the fitting using the same technique as is used for standing rigging to give a near-perfect connection. The parallel connection uses a separate connecting fitting, the BallConTM, that is secured to the electrode with a hex screw. This allows for a low-clearance (<3" from outer hull surface) installation when the cable has to run up the hull. The ball-shaped BallConTM connection also provides a large thermal capacity for heat dissipation.

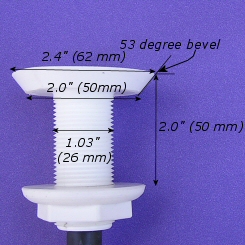

Though-hull fittings

Three types of through hulls are available, as shown below. The Flush and Mushroom head are Marelon and the Stainless is stainless 316. The vertical dimension shown gives the maximum hull thickness that can be accommodated. |

|

|

Flush-head through hull |

Mushroom-head through hull |

Stainless through hull |

Tip fairing

In the normal configuration there is an air space around the top ~0.5" to allow for cooling. In the faired option additional flame-retardant fairing is added to fill in the cavity and leave only the tip exposed. Since the tip is expected to heat up appreciably during a lightning strike this fairing is likely to blow out to an extent determined by the amount of charge that has flowed, possibly to a depth of 0.5". Thus the appearance of the fairing provides a useful indication of the energy dissipated at that electrode. Since the damage is cosmetic, there is little risk to the integrity of the electrode bedding. After a strike, inspect the fairing to determine the extent of pitting to both the tip and the fairing, clean off all carbon deposits on the electrode with solvent, and refair the damaged portion. Replace the electrode if the damage extends deeper than 0.5".Electrode with

no fairing |

Electrode with faired tip |

|

|

Sample configurations

Flush through hull |

|||

|

|

|

|

Electrode with

perpendicular connector |

Electrode with daisy-chain connector |

Faired electrode

with ECon connector |

|

Mushroom through hull |

|||

|

|

|

|

Electrode with parallel connector |

Electrode with EConTM connector |

Electrode in stainless through hull |

|

Contact

Marine Lightning Protection Inc.3215 NW 17th StreetGainesville Florida 32605 |

|

| Phone: +1 352 373-3485

Email: info@marinelightning.com URL: www.marinelightning.com |

|

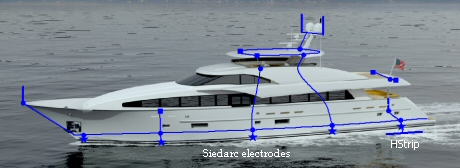

Providing exit terminals around the perimeter of the

hull is the key to an effective system design since it enables the

lightning down conductors to be routed externally to all wiring and

conducting fittings. The illustration

on the left shows a layout with six Siedarc electrodes and two HStrips providing

exit terminals from an external network of conductors. The port view is the same. That is, there are six electrodes, and two HStrips. This layout embodies the ExoTerminalTM lightning protection system.

Providing exit terminals around the perimeter of the

hull is the key to an effective system design since it enables the

lightning down conductors to be routed externally to all wiring and

conducting fittings. The illustration

on the left shows a layout with six Siedarc electrodes and two HStrips providing

exit terminals from an external network of conductors. The port view is the same. That is, there are six electrodes, and two HStrips. This layout embodies the ExoTerminalTM lightning protection system.